Comparing Diesel Types

Two Cycle, Four Cycle

by David Pascoe

Check out the Internet forums and you will see these questions asked over and over again: What is the best diesel engine choice for a boat. In a way, that is sort of like asking what woman you should marry, since the question is posed without any parameters. Or at least parameters that questioners are capable of defining.

Currently, there are three major diesel competitors, Detroit Diesel, Caterpillar and Cummins. Engines like M.A.N., MTU, Yanmar and Volvo have a much smaller market. Moreover, the differences between the engines offered by the three companies could hardly be much more different. Experience has shown that, like most manufacturers, they make some good ones, and occasionally some not-so-good ones. In terms of overall reliability, I’d rate them about the same -- all parameters being equal. Of course, that is an utterly useless appraisal. There are a huge number of variables that come into play, that can make engine selection something that requires very careful consideration whether you're buying a new or used boat. So, I’m going to explain in detail why this is a difficult question to answer, and why it is that choosing a particular manufacturer shouldn't be the only decision criteria. An awful lot depends on how you are going to run your boat, and the kind of performance and service life you expect.

WEB INFO UPDATE:

It's taken them awhile, but most engine companies now have

engine technical data posted on their web sites. Last year,

most did not, so this is good news for buyers wanting to do

technical comparisons.

There are two basic engine types, two cycle and four cycle. The former is represented by Detroit Diesel alone, while the later by both Cummins and Caterpillar and virtually all the others, for only DD makes two cycle engines. The differences between the two types is very substantial, with each having their pros and cons depending on the application of the engine.

Before I get into this, let me first dispel some myths about diesels. These engines developed their reputation for reliability and very long engine life beginning over a hundred years ago, a reputation that, for the most part, no longer holds. That reputation was based up very unsophisticated, slow turning, low horsepower engines. Except for sailboat auxiliaries, you won’t find many such engines in existence today. Today we have a "need for speed," and everyone wants to go fast. Going fast is what negates the virtues of those engines from a by-gone era.

The modern diesel is very sophisticated, complex, lighter weight and very powerful. Hence, their life span is often no more than that of a gas engine, often times even less. To say that they are delicate is not an overstatement. There is a very simple rule today that the more power you try to squeeze out of a given engine block, the less service life it will give. People can argue all they want to, but that is a fact.

Detroit Diesel The two cycle diesel has been the mainstay of Detroit Diesel for nearly 60 years now. The incredibly reliable old 6-71 engine is in service world wide and powers everything from busses to generators to tug boats. Its service record is unparalleled.

Two cycle and four cycle engines each have their pros and cons. The operating system of the two cycle is radically different than the four cycle, which operates more like an ordinary gas engine without spark plugs. The Detroit Diesel engine is unique and is not offered by any other manufacturer. This engine utilizes a moderately heavy cylinder block that is quite complex in its casting. Compared to a MTU or Volvo, it is light; compared with Yanmar or Cummins, it is heavy. It is a long stroke, smaller bore engine than most four cycles. The Cat 3208, for example, has a fairly short stroke, as do the Cummins V-8’s. This gives the Detroit engine considerably higher torque at lower speed ranges, but limits its top RPM range: the longer the stroke, the slower the engine has to run. Thus, higher power at lower speeds.

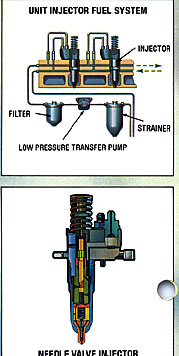

The Detroit injector system is just one of the major differences over four cycle engines.

Credit: Detroit Diesel Allison

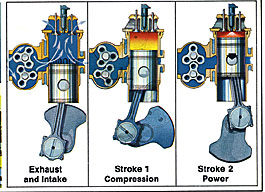

The two stroke cycle.

The push rods of these engines are also about 33% longer than most 4 stroke engines, creating more rotational mass and therefore more rotational torque. Altogether, the engine delivers more power from less displacement, lower speed, but higher casting weights, while fuel consumptions remain approximately the same.

The typical V-8 Detroit engine today has more than double the number of internal parts as say a Caterpillar V-8, making it a more sophisticated, but remarkably not more costly engine. Why not more expensive with all those extra parts? Well, there is a very good reason for that, which is that DD is the largest diesel engine manufacturer in the world. They sell a lot of parts, and higher production means lower cost. Typically, DD engine parts are considerably less expensive than Caterpillar parts. But there’s more to it than that. Most of all 71 and 92 series (can) use interchangeable parts. This interchangeability also has a tremendous effect on parts costs. It also means that world wide, there are more mechanics trained to work on DD than any other. Stocking costs are also much lower because of the interchangeability.

The downside to this engine is that these numerous parts do create something of a more serious wear problem over the four cycle with fewer and less delicate parts. This situation becomes magnified with poor maintenance, and therefore they do require more care, though not necessarily at significantly higher cost.

How It Works The DD four exhaust valves and a blower, compared with a four cycle with only two valves and no blower. Each cylinder liner has a row of 14 oblong holes near the bottom. After the compression stroke, the piston travels downward, past this row of holes. This is similar to the way an outboard motor works. Except that once the piston goes below the holes, called scavenging ports, the blower forces air in at high pressure from what is called the air gallery cast into the block. Thus, the DD has not only water jackets, but air galleries cast in the block as well. This one thing that makes DD blocks more complex.

The pressurized air then "scavenges" or forces out the burned gasses up through the four exhaust valves. This enables the engine to make only two revolutions to complete the combustion cycle rather that the four required of the four cycle engine, which relies on a second upward stroke of the piston to exhaust the cylinder of burned gas. In theory, this makes the engine more efficient. In reality, all the friction caused by all those extra moving parts eats up some of the efficiency gain. Why? Because of the drag created by the non-compression stroke, and the power to drive the blower and extra cam shaft. Even so, there is a major power gain through this design.

So the DD engine is left with certain advantages such as more immediate power delivery and higher power at lower speeds. This is one of the things that has made these engines more popular with the commercial boat industry. The four cycle engine has to throttle up to a higher RPM before a similar amount of power is delivered to the propeller.

The fuel systems are both very different and yet similar. The DD has no fuel injector pump, but rather each injector is it’s own fuel pump. An injection pump is sort of like a small engine with 6 or 8 cylinders and pistons that pump and supply fuel to the injector which, in a four cycle engine is nothing more than a spray nozzle like on the end of a garden hose, albeit a bit more refined. On a DD engine, each injector is operated by the dual underhead camshafts that are immediately below the head.

A Detroit Diesel uses its fuel as part of the cooling system to the cylinder head and injector. It returns a LOT of fuel back to the tank, and it is very hot. Thus, a DD has a fuel oil cooler, whereas the four cycle does not. With Detroits, you have to worry about the state of fuel return to the tank when, for example, you decide to run off of one tank only. Detroits for the most part are self-priming fuel system. Woe to the captain who gets air into the fuel system of a four cycle engine system. You got to get that air out, or it will not run.

Now here is where the DD gets all those extra working parts. Each cam shaft has three lobes per cylinder. Two to run two pairs of exhaust valves and one to run the injector. All are actuated by roller followers placed in the head with a very short "pushrod." This actuates the injector plunger that pressurizes the fuel and squirts the vaporized fuel in the cylinder.

Unlike a 4 cycle, the fuel metering is all controlled by the injector and a throttle control lever on the injector actuated by the "rack," just a long bar that controls all injectors simultaneously. "Adjusting the rack" is how you tune a DD fuel system. If the rack is not adjusted properly, the injectors will get either too much or too little fuel and the owner won’t have a happy face. Between the two engine types, the injectors are the main show on DD engines; the fuel pump is the big deal on 4 cycle engines -- i.e. the gizmo that eats the most greenbacks. On a DD individual injectors can go bad without jeopardizing the whole system. With a 4 cycle engine, when the fuel injection pump goes, its lights out. Two advantages of the DD fuel system is that it is considerably less sensitive to fouled fuel, plus the injectors are self-priming so that you don’t suffer the priming problems often encountered with 4 cycle engines. While the injection pump system is more reliable and requires less frequent service, the DD injectors are more efficient.

The blower and turbocharger aspiration system constitutes another major difference. The four cycle engine is aspirated through intake valves next to the exhaust valves; the DD engine has only exhaust valves, but twice as many of them. The DD cylinder heads are very complex and expensive to replace if one gets damaged, such as cracking from overheating. All those extra working parts make for more potential trouble, but also increase efficiency considerably. This why, pound for pound, DD squeezes quite a bit more horsepower out of their engines than CAT does.

Cummins Model QSM11 Marine Engine

Crankshaft power (high output) 474 kW 635 hp

Crankshaft power (intermittent) 433 kW 580 bhp

Crankshaft power (high output) 399 kW 535 bhp

Rated speed 2300 rpm 2300 rpm

Bore x stroke 125x147 mm 4.92x5.79 in

Displacement 10.8 liters 661 cu in

Number of cylinders Inline 6

Engine weight w/o gear 1125 kg 2,475 lb

Fuel consumption Liters per hour 124.9

Gallons per hour 33.0

Compare the specs of this Cummins engine with that of a Detroit of comparable power rating. Isn't it interesting that this new Cummins engine only turns 2300 rpm? Note that the Detroit weight includes gear, while Cummins does not, typically another 400-600 lbs depending on engine size.

Other significant differences include the large auxiliary drive housings on the Detroit. As mentioned, these are basically commercial engines, and the drive housing is designed to drive other components such as pumps, air compressors, even alternators through a gear drive rather than the belts you get on a four cycle. This is the large housing you find on the back of the engine and is full of gears. This becomes significant in larger yachts where you may want to drive a powerful hydraulic pump for things like stabilizers and bow thrusters. With a four cycle, you have to go through a lot of rigmarole setting up belt drive pumps, whereas there is a ready made pump to do whatever job you need from your Detroit. Need an air compressor? No problem, just buy it and bolt it on. No muss, no fuss.

Turbochargers and Blowers Turbochargers are similar to jet engines. It has two sides and two turbines. The exhaust side has the turbine immediately after the exhaust manifold and uses the rushing hot exhaust gasses to turn it. The other turbine is attached to the same shaft, and pulls fresh air in and forces it into the air induction system. Because the turbo gets hot, it also heats up the air on the intake side, which is why you have to have an intercooler to reduce this air temperature. Remember, we said that the higher the intake air temperature, the lower the engine performance? Ergo, when you’re intercooler gets dirty, you loose engine performance.

You might wonder why, if the Jimmy already has a blower (which I have described as doing the same job of evacuating exhaust gases), why do they put turbochargers on it? Well, simply because the blower can only blow so much air. The turbo will increase the air flow proportional to engine speed. It simply forces yet more air to the blower, thereby increasing the speed and completeness with which the exhaust gasses are evacuated from the cylinder. They call it "boost," and it doesn't kick in until the turbo pressure exceeds the blower pressure.

The turbocharger simply adds more air pressure to the "Jimmy" blowers. You know, those big things sticking up on the top of the old time drag racers made famous by the likes of "Big Daddy" Don Garlits, and how they took an ordinary car engine and squeezed 1,000 hp or more out of it for about 15 seconds. That’s all the longer the engine would last! What a diesel blower and turbo does is to evacuate the exhaust gasses faster and more completely. And it also greatly reduces the internal cylinder temperature. A diesel has no spark plugs. The fuel is ignited by compressing it until it explodes under extreme pressure, about 550 psi. It explodes because the pressure causes the fuel and air to heat up. This heat has to be gotten rid of or we have a big problem on our hands. The blower is a big help.

You can probably appreciate that if the cylinder is not cooled down before the next compression cycle, the temperature inside the cylinder is going to be rather hot. Thus, when the piston comes up and starts compressing the atomized fuel, it is going to exploded SOONER because the cylinder air temperature is higher. It's a matter of timing. This is bad news because the detonation is going to occur a few nanoseconds before the piston reaches top dead center. This throws the engine timing off and can result in acute loss of power and other serious problems. Like connecting rods through the block.

Now, this can happen in both 2 and 4 cycle engines, so now you know why maintaining the intercooler and heat exchanger in tip top shape is of extreme importance to your engine’s health and longevity. Neglect it and Big Bill is going to knock on your door sooner rather than later.

The bottom line is that the Detroit Diesel gets more power from a slower turning engine with fairly light weight engine castings (by yesteryear's standards). Keeping the engine speed down is very important to longevity.

The four cycle engine doesn’t have this abundance of extra parts. It is a simpler and more basic engine. You might think, aha, that’s great, simplicity is good. Yes, it is, as long as you don’t want to go fast. Problem is, you do, and so now we are going to subvert the benefits of simplicity to achieve more power. This is done by pumping in more fuel and turning the engine faster, usually around 400 to 600 RPM faster than a DD. That may not seem like much, but to a diesel it’s around 25% faster. Now all your benefits of simplicity and long life have just gone down the drain because you want to go fast.

Now we’re back to square one with the Cat and DD engines evening out on the overall scorecard except for one thing. All things being equal, engine longevity between the two averages out to about the same. But you get quite a bit more power out of the DD than the Cat for each cubic inch of displacement.

Probably the most outstanding feature of the DD engine is its versatility in terms of power ratings. Any DD engine can be run at a broad range of power ratings by making relatively minor changes at fairly low cost. This is not possible with four cycle engines, and is one of the things that has endeared DD to the marine industry. For about $1200 you can just change injector size and change the power rating, particularly downward if you want to depower. Increasing injector size, of course, is going to reduce engine life. Again, this is possible because injectors are self-metering and a wide range of sizes is readily available.

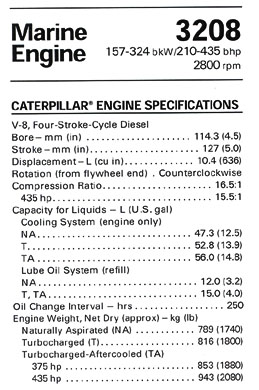

Caterpillar DD engines tend to be large due to the long stroke, complex engine block and more components. You won’t find many 6V71’s or 92’s in the 30-40 foot range boats because it’s a hard fit. The short stroke Cat 3208 engine is one of the most popular in this size boat because it has a very low profile: it fits, allowing boat designers to create low profile boats with adequate headroom.. Given your druthers, you might take a pair of 500 hp 6V92’s over a pair of 400 hp Cats any day. Problem is, on smaller boats, you have to give up some interior space to make the DD’s fit. Mama don’t like that, so you end up with lower power. Such is life in the fast lane.

So why can’t you get a higher powered Cat? Well, they tried running the 3208 up to 475 hp and that smaller block just couldn’t handle it. Best it can do is 425, and even then they had to lower the compression and ended up with a smokier engine. This engine does best at 375 hp.

Yes, Cat does make the long stroke, inline series engine but now you are back to the same old high profile engine again. To make matters worse, with say the 3176 rated at 500 hp, you now have a bigger, heavier engine running at a higher speed and more fuel to give the same power as the little 6V92 does with the same space requirement. So which would you want? Pick ‘em.

The Cat 3208 is a good, reliable engine that, like all engines, will give you good, reliable service as long as they’re not souped up. They will do very well at pushing boats in the 32-38’ range, and do fairly well at pushing larger boats that have flatter bottoms and running at lower speeds, say around 20-22 kts. Where they will fall down is in a larger boat with a deeper vee, simply because of the inefficiency of the hull. Using a pair of 425 hp 3208’s to move a heavier, deeper vee 40 footer is not a good idea. At this point the boat will need the heavier 3176 engine or DD’s.

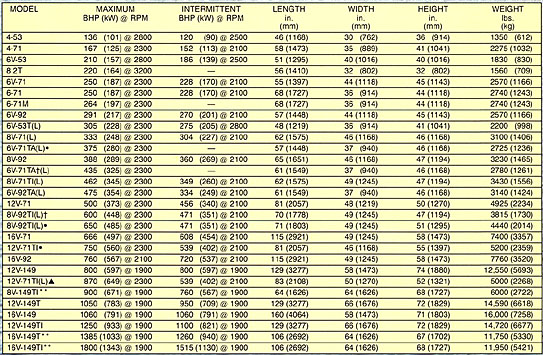

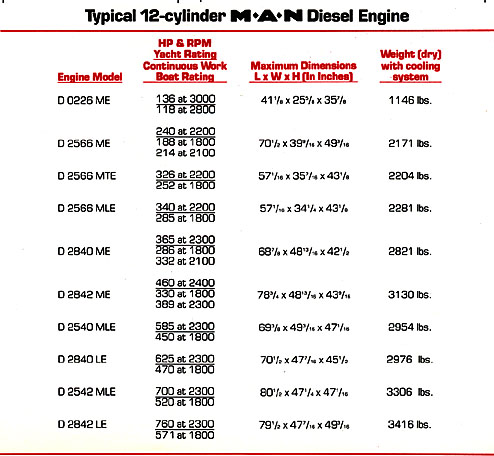

These tables show the relative weights and power ratings of MAN and Detroit Diesel. Note that in most cases, the Detroit is a heavier engine.

Now take a look at the Caterpillar 3208 specs in the table below. Notice that it's displacement is is 636 cu. in., more than 100 cu. in. greater than the 6V92 at 522 cid. So why is it that they're squeezing 550 hp out of the Detroit, and only 435 hp out of the Cat? Why can't they get 600 hp out of it? Here is where my 1:1 displacement/hp rule takes a dump. Why? Well, again, compare engine weights. The Cat is a light weight engine at only 1740 lbs WITH GEAR. It does not have replaceable liners and is a throwaway block. Plus it runs 500 rpm faster. That very light weight block cannot handle either the increased stress and heat increases that more power puts out.

Where's the beef? Well, it's not there. If you could see a 3208 and 6V92 sitting together side-by-side on the floor, you'd be blown away at the difference in overall size. The smaller displacement 6-V92 is ONE THIRD physically larger than the Cat. Beef is one of the key ingredients to higher power and reliability. The amount if iron contained in the block makes a difference. This is a problem we have with all automotive conversions. Lightness is fine for automotive use because it doesn't need those high powers, whereas in marine engines, we do. The Cat big block engines have always performed better because these were built for industrial applications. It's been much the same for Detroit. Except for the 6-71 in busses, their engines are rarely used in on-road applications. Heavy equipment, yes, trucks, no. Cat and Cummins have the automotive market, which they serve well.

The bottom line is that the 6V92 and the two cycle engines are substantially more efficient engines, but you pay a premium in weight and the space to mount it in. In terms of power out equivalency, the 3208 and 6-71 are similar, though the edge for endurance goes to the 6-71. Both engines in their non-turbocharged versions will darn near last forever with good care.

The Effects of Turbocharging A four cycle diesel relies upon piston suction to draw air into the cylinder. This creates a lot of drag, but is much better at dissipating heat. For all performance engines, getting rid of the heat of combustion is a major problem. When a turbocharger is added, it eliminates this suction and forces air into the cylinder at a much faster rate, as well as being under pressure. Problem is, that turbo air is hotter, so it results in a temperature increase, even with intercoolers. Even though the turbo creates extra drag itself, it also allows each cylinder to get a large shot of fuel. This results in a disproportionately large increase in power, which is why they do it.

But you've already figured the downside, haven't you? Yep, more fuel results in even more heat. Increased heat AND power is a double whammy that causes a net reduction in engine life. Never mind the effects of just increased strain alone. This is no different than the human body. You can work it just so hard before it begins to break down. Another effect is that the higher the power output, the more critical maintenance becomes. The neglected maintenance that you could get away with on the lower power engine won't be tolerated at all with the high performance version. Minor injuries will put these babies out of the game fast. That old 6-71 at 250 hp that would chug along for decades with total neglect, will fly to pieces at 435 hp with a minor cooling system problem. Why? Because it was never designed to dissipate those kind of heat build ups. With that kind of power, there is no such thing as a minor overheat. Every little deficiency becomes a major fault.

Which to Choose? For smaller boats -- under 15,000 lbs or so, it probably doesn't make that much difference because the available choices are so few. The one critical feature should be the hp/displacement ratio of not more than 110% or so.

For boats at 20k lbs and above, pushing those weights without excessive engine strain becomes a major issue. Here's where the big, beefy blocks really stand out. I write all this stuff so you can understand the why's and wherefores of making good choices. There's nothing like knowing the reason why you should spend more money for something. There are lots of places you can cut corners, but engine selection shouldn't be one of them.

The Cat 3208 remains a good choice for medium size boats where high speed is not the issue. These engines definitely do better in lighter boats at lower speeds. They're a lot less good for pushing one of those 40k Taiwan trawler types at 21 knots.

The other little Cats? Un, uh. Someone's gotta prove to me that we're not going to be seeing any more of them yanked out and sitting on the docks. I just tripped over a less than one year old 3116 engine yesterday.

For high speed in a moderately light, express type mid sized boat, the Cummins seem to be performing well. As I've said, they've not been around long enough to know for sure.

For your larger boats, and very heavy smaller boats (e.g. small Hats, Berties, etc.) I still think the Detroits are the best way to go, both from a cost and reliability stand point. Here your choices expand to MAN and MTU, but when considering both initial cost and repair and maintenance costs, these engines are enormously expensive. Nor are these German engines quite as reliable as many people are led to believe. These engines have had their fair share of design faults also.

Engines such as the 12V92 have not compared as favorably as the 12V71, though the later is capable of less power. Former has had considerably less average engine life than expected between overhauls. In part, that has had to do with the hot rod applications they're subjected to, so it's hard to know how they fare in something other than hotrods. This basic engine was initially offered at 850 hp @2300 but is now up to 1110 hp. The 1040 hp versions have done fairly well when properly matched to load. 2000 hrs between overhauls is not uncommon.

The 6-71, 6V92 and 8V92 perform well at reasonable horsepowers. For overall longevity, I'd opt for the 6-71 in any boat where the power range is applicable. Reliability is without parallel. In the hot rod class, I'll take the 6V92 at less than 550 hp while being prepared to follow the maintenance guide religiously. This is a spectacular little power plant for those that like to push the 30 knot envelope in a mid size boat.

The 8V92 would fall into the same category, except that the modifiers like JT, S&S and Covington try to squeeze too much power out of these blocks. A good deal at 735 hp and below. A poor choice above that.

For lightweight or smaller hotrods, the 3208 will do fine, with the same caveat as above.

When money is not the issue, by all means play around with the German diesels. Just beware that you're not going to get them fixed for the price of a Detroit. As with Mercedes (to whom they are related), those people aren't shy about pricing. They stick it to you good.

What about the others? Well, another year has gone by and all we've seen are the Big Three. It's always been the case that big diesels are too expensive to fool around with. The best choices are those with the best track records. Especially when buying used boats where the warranty is signed by your own name.

Load Matching The criteria discussed above are not the only factors. Of late we have been running into a lot of propellering problems. If the builder puts the right size on, the owner starts fooling around with exotic propellers trying to make it go faster. Engines become overloaded and accelerated wear takes over. When this happens, all bets are off. Other factors include badly balanced boats which don't trim out properly, resulting in engine overloads.

Repowering We get a lot of questions about how to go about repowering a boat. Particularly the conversion of gas to diesel. Let me just say that to do this properly requires a degree in higher education, particularly engineering and naval architecture. If you think you can just slap a pair of engines in there with only a few, inexpensive modifications, you are mistaken. If you're not willing to pay the cost of an expert engineer, then you're on your own. But be prepared for some very major and expensive disappointments.

Current Trends In recent years there has been much talk about light weight, higher power diesel engines. We all thought that Yanmar was going to lead the way with their little truck engines with all those aluminum parts hung on them. This hasn’t happened, and it’s a good thing, too. A few years ago, Caterpillar introduced their 3100 series of new 6 cylinder engines. These are moderate weight engines with as low profile as one can get with an inline six.

Yet nearly every one of this line has experienced severe cylinder head design problems with these souped up applications. Cummins, with a similar type engine, has been grabbing their market with their record of better reliability, at horsepowers considerably beyond what I would have thought they could get away with. However, even the Cummins late models haven’t been in use long enough that we’ve had time to get a handle on general service life.

The problem with diesels, you see, is that unless an engine has design problems, it takes about 15 years before we get a handle on longevity. Only a surveyor gets to see a hundred or more set of engines per year closely, and in actual service. The design problems we learn about in a hurry, as boat owners start making a bit of a fuss when engines crap out early. On the other hand, if we had judged the 6V92 by its first few years in service (it had beaucoup problems), it wouldn’t exist today. Unfortunately for Caterpillar, they’ve allowed their cylinder head problems to hang around too long. Whatever one might have to complain about Detroit Diesel, at least whether it be GM or the Penske group, they’ve managed to keep their customers happy. Their response to problems has been excellent over the years.

Fortunately, ideas about light weight, hot rod diesels are dying a natural death. It’s hard enough making the moderate weight engines last a reasonably long time. Moreover, the reduction in weight is not needed, as people are discovering that ultralight boats make for unpleasant experiences on rough water.

There’s just no getting away from the fact that if you want reliability and economy, keep it heavy, and keep it slow, and around 1:1 on the hp/displacement ratio.

And one more thing. Don't power your boat on the margin. Give it a bit more power than you think it needs. That way engines don't strain as much to give you the speed you want. You're going to pay for what you need one way or the other, be it on the front end, or on the back.

Posted December 11, 1999

Visit davidpascoe.com for his power boat books

Visit davidpascoe.com for his power boat books

David Pascoe is a second generation marine surveyor in his family who began his surveying career at age 16 as an apprentice in 1965 as the era of wooden boats was drawing to a close.

Certified by the National Association of Marine Surveyors in 1972, he has conducted over 5,000 pre purchase surveys in addition to having conducted hundreds of boating accident investigations, including fires, sinkings, hull failures and machinery failure analysis.

Over forty years of knowledge and experience are brought to bear in following books. David Pascoe is the author of:

In addition to readers in the United States, boaters and boat industry professionals worldwide from nearly 80 countries have purchased David Pascoe's books, since introduction of his first book in 2001.

In 2012, David Pascoe has retired from marine surveying business at age 65.

On November 23rd, 2018, David Pascoe has passed away at age 71.

Biography - Long version